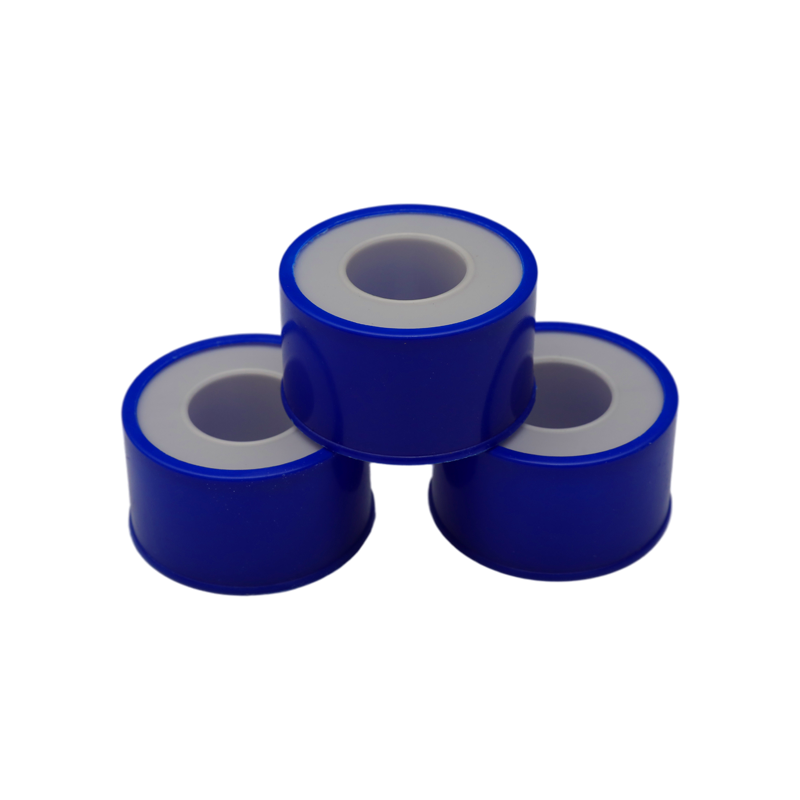

The relationship between the chemical stability and abrasion resistance of 25mm Teflon tape is essential for understanding its performance in various applications. Both properties contribute significantly to the material's overall utility, especially in industrial and specialized settings.

Teflon, or polytetrafluoroethylene (PTFE), is known for its remarkable chemical stability. This stability is attributed to the strong carbon-fluorine bonds that make up its molecular structure, which resist degradation from a wide range of chemicals, including strong acids, bases, and solvents. This property allows Teflon tape to be used effectively in applications where it may come into contact with corrosive substances, such as in chemical processing, pharmaceuticals, and food processing.

The chemical stability of Teflon tape enables it to maintain its physical and mechanical properties even when exposed to harsh chemicals. It does not swell, dissolve, or degrade, which is crucial for applications that require reliable sealing and insulation. This stability also means that the tape can be used in high-temperature environments without losing its integrity, as it can withstand temperatures up to 260°C (500°F).

Abrasion resistance refers to a material's ability to withstand mechanical wear and tear due to friction, scraping, or impact. While Teflon tape possesses some level of abrasion resistance, it is generally not as durable as materials specifically engineered for heavy wear applications. The smooth surface of Teflon reduces friction, which can help minimize wear when in contact with other surfaces. However, in environments where the tape is subject to constant movement or contact with abrasive materials, its surface may wear down more quickly.

The performance of Teflon tape in terms of abrasion resistance is influenced by factors such as the thickness of the tape, the type of surface it is applied to, and the conditions under which it operates. Thicker tapes may offer better durability and resistance to wear, while the nature of the contact surface—whether rough or smooth—will also play a critical role in how the tape holds up over time.

Understanding the relationship between chemical stability and abrasion resistance is crucial for evaluating Teflon tape's overall performance. These properties are interlinked but also present a balancing act in many applications:

Combined Effects: In applications where Teflon tape is subjected to both chemical exposure and mechanical abrasion, its chemical stability allows it to resist deterioration from corrosive agents. However, if the tape is continuously exposed to abrasive conditions, the wear can compromise its sealing effectiveness, regardless of its chemical stability.

The effectiveness of Teflon tape will depend on the specific operational environment. For instance, in a chemical processing plant where the tape is exposed to corrosive substances but not significant abrasion, its chemical stability will be the dominant factor. Conversely, in an application with high mechanical wear—such as conveyor belts or moving machinery—the tape's abrasion resistance will become critical.

Depending on the intended use, the selection of Teflon tape may involve a trade-off between these properties. If a high level of chemical exposure is anticipated, a thicker or more specialized tape may be chosen, even if it means some compromise in abrasion resistance.

There are ways to enhance the properties of Teflon tape. For instance, certain formulations of Teflon can incorporate fillers or coatings that improve abrasion resistance while maintaining chemical stability. Alternatively, in environments where both properties are critical, users may consider combining Teflon tape with other materials designed for high wear applications.

The relationship between the chemical stability and abrasion resistance of 25mm Teflon tape is vital for its application in various industries. While Teflon’s chemical stability allows it to resist degradation in harsh environments, its abrasion resistance is crucial for maintaining performance under mechanical stress. Understanding this interplay helps in selecting the right tape for specific applications, ensuring optimal performance and longevity. Balancing these two properties is essential for maximizing the utility of Teflon tape, particularly in demanding industrial settings.

English

English Español

Español